Products Digital Services

Process data visualization and analysis

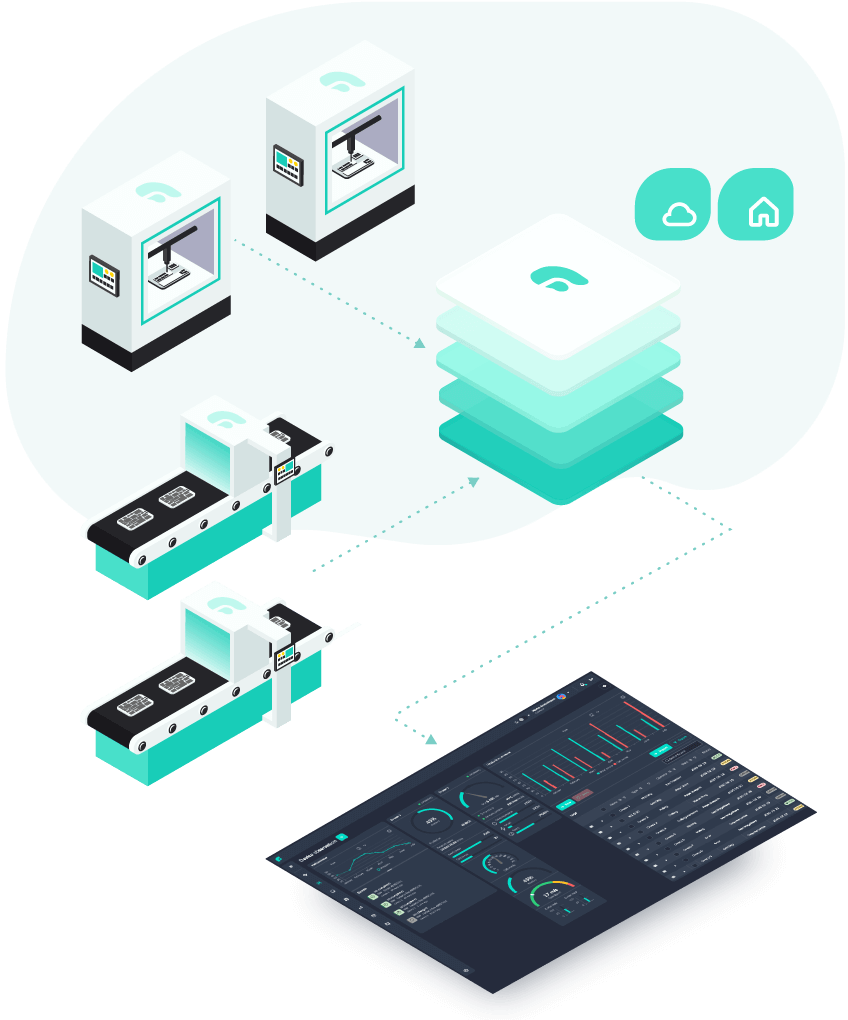

Keep everything in view with Factopilot®.

Visualization of processes

Schoeler is consistently developing new standards in process data acquisition in order to raise our Industry 4.0 standards for new machines, but also for existing equipment in the market. With the Factopilot® software specially developed for data recording and evaluation, our customers can monitor and control their equipment on site or remotely via any HMTL5-capable web browser.

Whether it is a matter of individual, stand-alone machines, interconnected systems or entire manufacturing processes at one location or remote sites, Factopilot® is the all-in-one tool for bundling, visualizing and analyzing all data on just one device. The central key features of this software solution are its simple configurability, scalability and intuitive operation. Machine operators, production planners, supervisors or even service personnel, each user can put together their own view of things and visualize the process in the way that makes the most sense for them.

Analysis and diagnosis of data

The stored data can not only be visualized, they can also be easily combined with each other for analysis and diagnosis purposes. Through this intelligent pairing of all data, Factopilot® plays out its full potential and even enables the comparison and optimization of parameters across machines in order to coordinate entire production chains. Service personnel can take the advantage of predictive maintenance features and thus avoid unplanned production downtimes. Consumables can be used optimally, thus saving resources in a targeted manner.

- Visualization and control with any HTML5-capable web browser

- Wireless visualization via mobile devices

- Location-independent real-time access via the network or the internet

- Control room visualization of entire process chains on just one screen

- Adjustable standard dashboard configurations for different machines

- Easy configurability through ready-made widget libraries

- Extensive analysis functions

- Data diagnostics via ready-made charts and lists

- Combination of information from multiple machines on one dashboard

- Freely programmable notification system for email or push message

- Error and machine status evaluations for process analysis

- Combination of evaluations across several locations

- Central control of service calls

- Control of production flows through intelligent data evaluation

- New installations are Factoready, i.e. prepared for the use of Factopilot®.

- Open interface for processing data via an OPC-UA interface for integrating further data sources

- Easy scalability via flexible license model

- Intelligent linking of machines via Factomaster

- Developer API (REST/GraphQL)

- Evaluation of all data and IO-Link components available on the PLC

- Can be used as an OEM (white-label) solution for open platforms as an additional process

- Data backup on local data carriers or through cloud solutions

Remote service with augmented reality

In line with current trends, Schoeler is breaking new ground. An efficient way of working with state-of-the-art equipment is indispensable. Fast and clear communication is an essential factor. With the use of augmented reality (AR) data glasses, our service is optimized by an additional tool.

- Our service technician comes to you virtually

- He sees what you see and gives troubleshooting tips

- Get help in 3D with just one call

- Premium AR glasses from the market leader

- Microsoft® Hololens 2 - based on Windows 10

- Data-protected and safe work with Microsoft® Teams

The AR data glasses form the link between the service technician on site and the engineers at Schoeler. The team in Germany can see live what the service technician at the customer's site sees in reality and we can receive additional information for support. The AR data glasses can also provide support during the initial commissioning of a complex machine. This improves communication and shortens the time for commissioning and troubleshooting. In this way, we can carry out service calls in the fastest and reliable manner, even when travel and quarantine restrictions make service trips to our customers difficult.