Products Automation

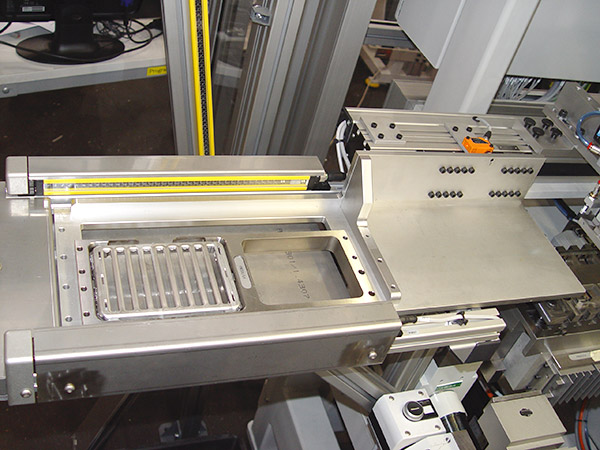

Semi-automatic core building ZZH

Flexible multi-row core buildering

The semi-automatic assembly lines of the type ZZH are used wherever a fast tool change is required to increase efficiency due to the high product variety. Whether the requirement is for a single-row radiator for the automotive sector or a multi-row system for truck applications, the ZZH always offers the highest degree of flexibility and productivity. Options for further automation such as tube or component allocation from magazines, single to six-row heat exchanger designs, individually adjustable tube end flaring or assisted heat exchanger removal can be selected for the ZZH. In this way, the best repeat accuracies and reliable product qualities can be achieved with a semi-automatic assembly process, independent of the operator.

.

Automatic core assembly line ZZA

Assembly lines for radiators, condensers, charge air coolers

The core assembly lines of the ZZA 300, 400 and 600 series can produce radiators, condensers as well as charge air coolers in standard sizes for the automotive or heavy-duty sector. For this type of machine the focus is on high product accuracy, flexibility and quick-change capability between the different models and product groups. The automatic core assembly lines are specially developed for medium and high production capacities. The individual components of a heat exchanger are assembled automatically so that the core can be fed directly to the subsequent brazing process. Operator intervention is reduced to a minimum with these systems.

Automatic core assembly line - compact

Assembly lines for compact charge air coolers

The ZZA 800 core assembly lines are designed primarily for the assembly of compact intercoolers with medium and high production rates. The individual components of a heat exchanger are automatically assembled so that the core can be fed directly to the subsequent brazing process. The manufacturing process is optimized for the automated production of small product sizes in order to achieve maximum efficiency. Depending on the requirements, different degrees of automation can be offered to achieve an exact match to the manufacturing process.